High-Density Polyethylene (HDPE) sheet is extremely strong against impact, abrasion-resistant, and exhibits a low coefficient of friction. The material is also moisture, stain, and odor-resistant, and is FDA approved for use in the food processing industry (mainly for cutting boards). The material’s durability makes it a perfect match for a variety of applications such as water tanks, chute linings, bottle/bottle cap production, and numerous other industrial uses. Borated HDPE offers radiation protection in nuclear facility applications.

High-Density Polyethylene (HDPE) sheet is extremely strong against impact, abrasion-resistant, and exhibits a low coefficient of friction. The material is also moisture, stain, and odor-resistant, and is FDA approved for use in the food processing industry (mainly for cutting boards). The material’s durability makes it a perfect match for a variety of applications such as water tanks, chute linings, bottle/bottle cap production, and numerous other industrial uses. Borated HDPE offers radiation protection in nuclear facility applications.

PTFE has the highest melting point and is capable of continued service at 500F(260 C). FEP is a melt-processible resin capable of continued service at 400F(204 C). PTFE products are used as gasket and packing materials in chemical processing equipment; as electrical insulation for maximum reliability; and in bearings, seals, piston rings, and other mechanical applications, especially those requiring anti-stick characteristics. PTFE has excellent thermal and electrical insulation properties. And, it has a low coefficient of friction.

HDPE (High-Density Polyethylene) vs Polymer PTFE/FEP Machining

Material Applications

HDPE (High-Density Polyethylene): Arena Board (puck board); Ballistic plates; Chemical resistant piping systems; Coax cable inner insulator; Fuel tanks for vehicles; Corrosion protection for steel pipelines; Geomembrane for hydraulic applications; Geothermal heat transfer piping systems; Meter & Valve Boxes.; Natural gas distribution pipe systems; Telecom ducts.Polymer PTFE/FEP: Cabling solutions; non-lubricated bearings; O-rings; Seals; Capacitors; Semiconductor Manufacturing; High-temperature electrical parts; Gaskets; Valve components.

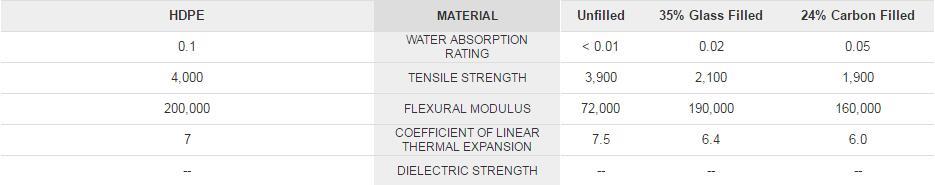

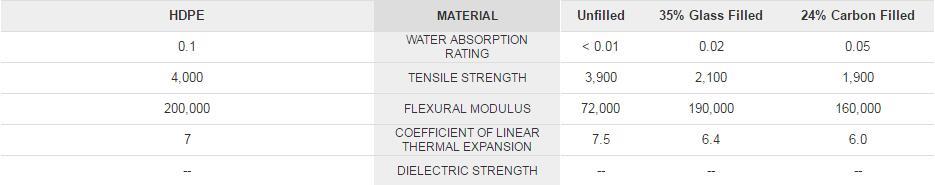

Material Properties

HDPE (High-Density Polyethylene): Can withstand temperatures of 120 ° continuously; Good tensile strength; Machinability; Low moisture absorption.Polymer PTFE/FEP: Excellent dielectric properties; Inertness to most chemicals; High heat and chemical resistance; Very low coefficient of friction; Excellent radiation resistance; Zero moisture absorption; Relatively insensitive to power frequency; Machinability.

Post time: Jun-15-2020